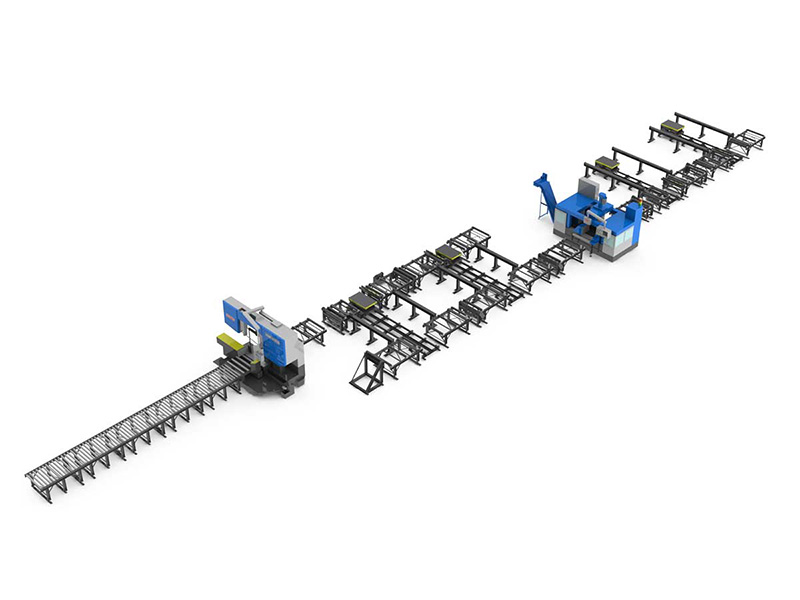

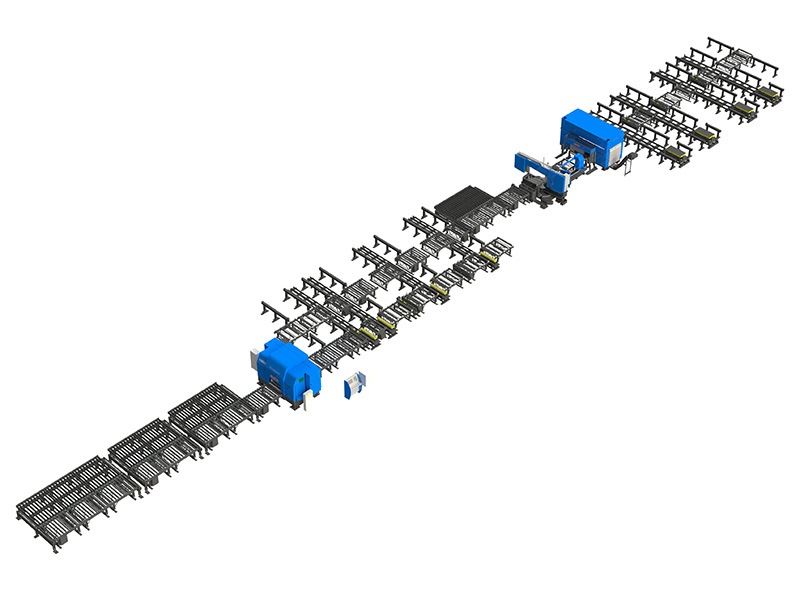

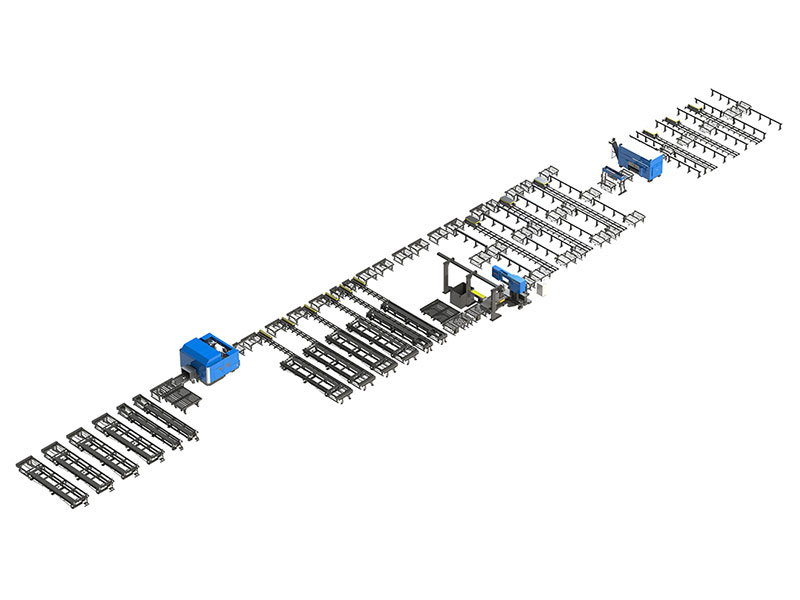

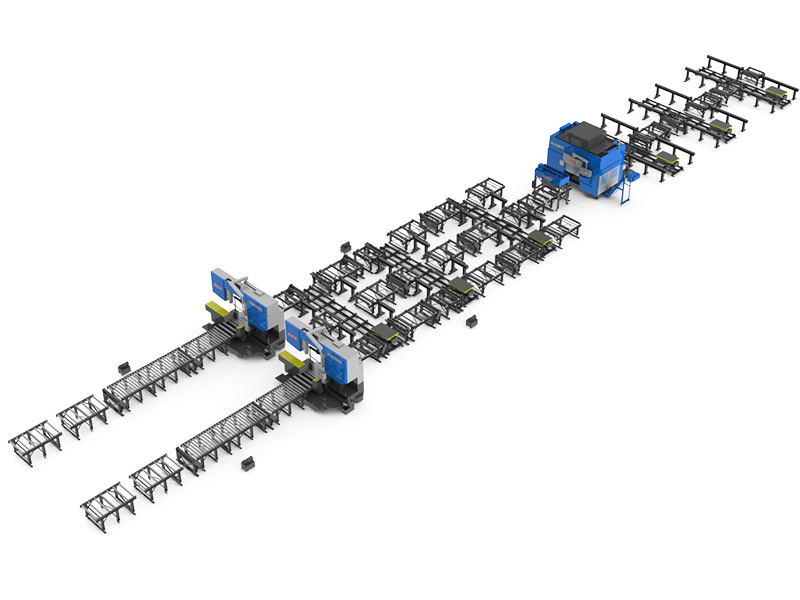

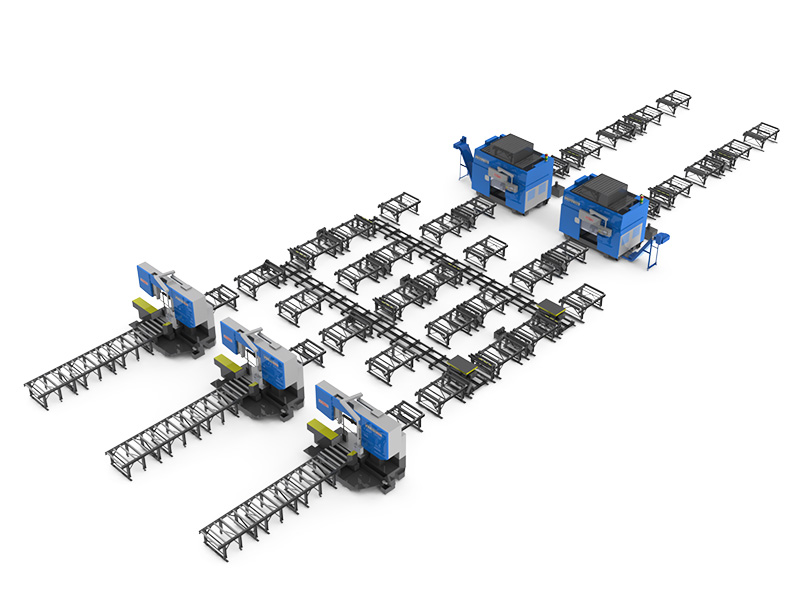

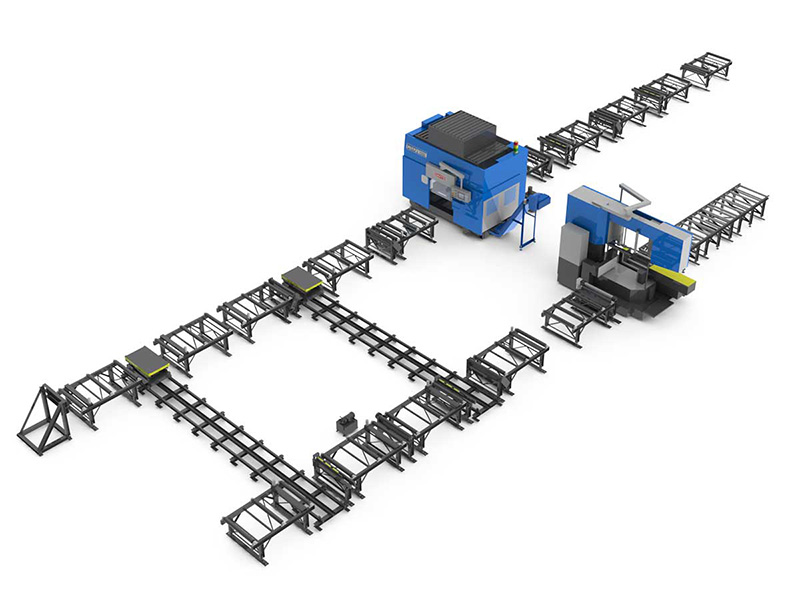

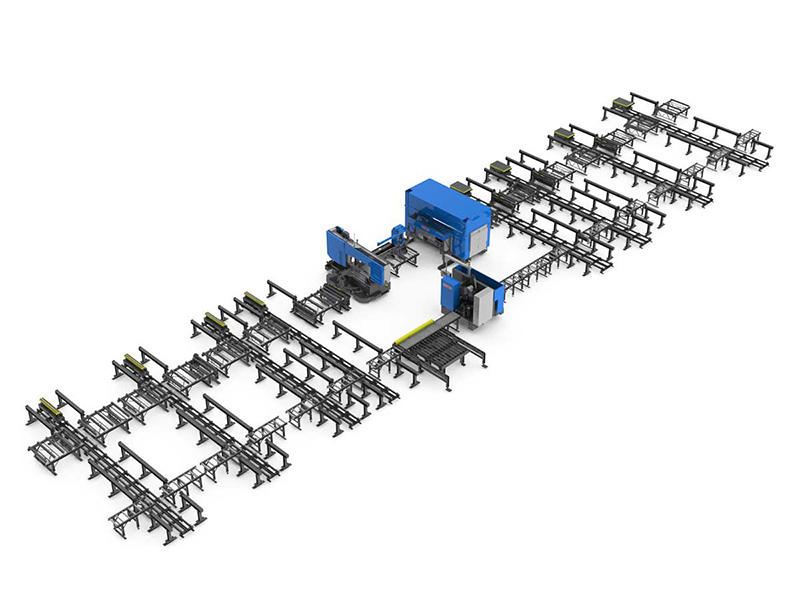

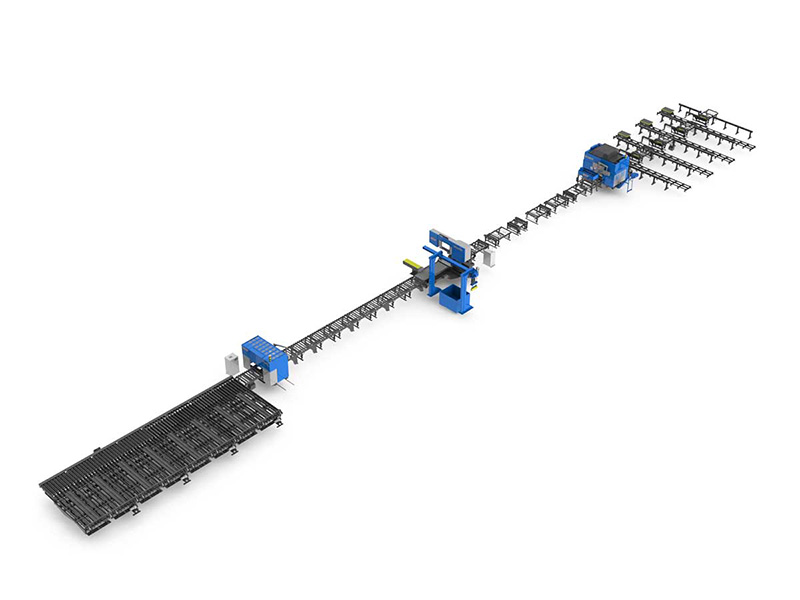

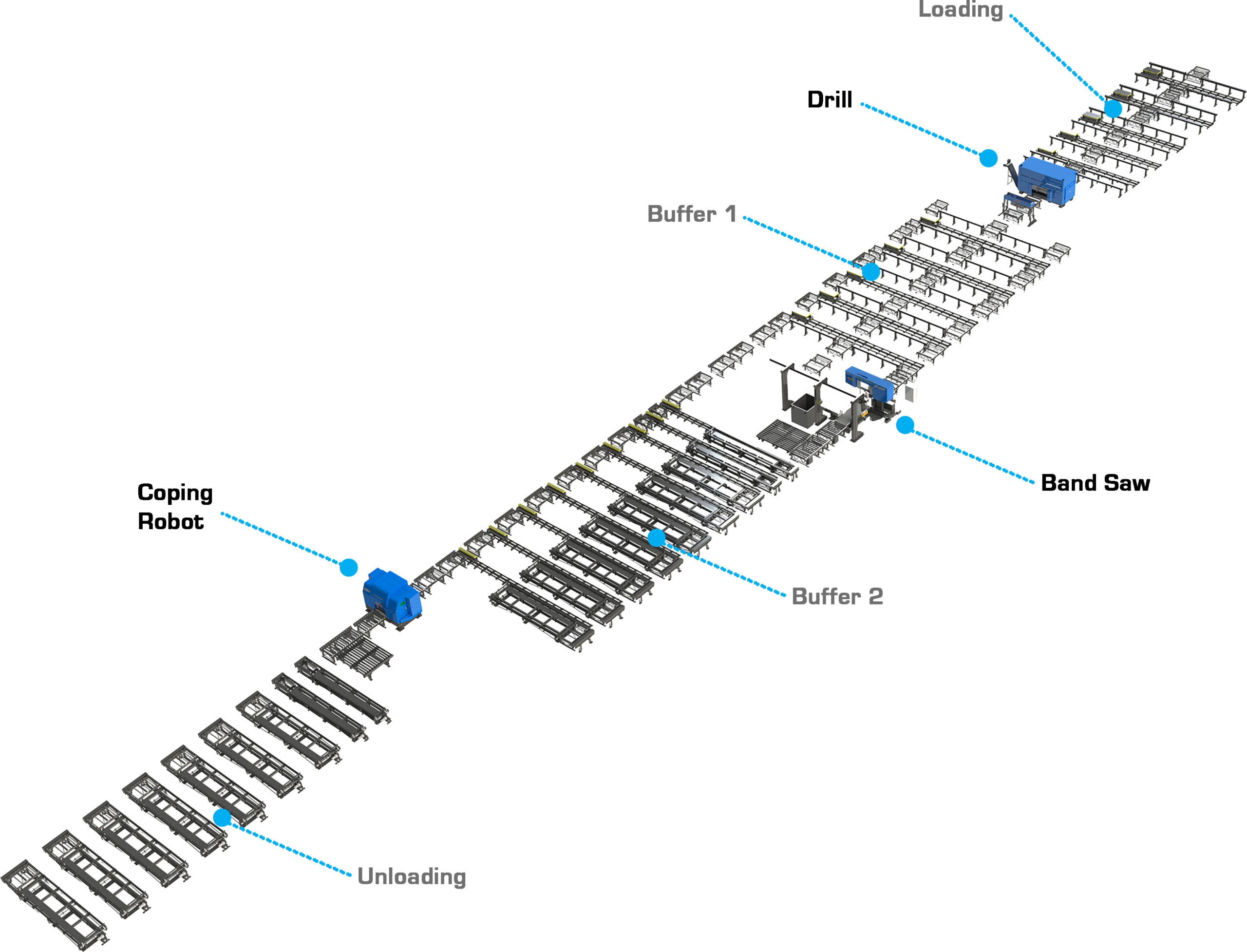

DAITO MULTI-MACHINE LINES

Machines are separated but still communicating with each other and connected with buffers in between, reducing bottlenecks. For added flexibility, Daito can offer multiple loading and unloading stations.

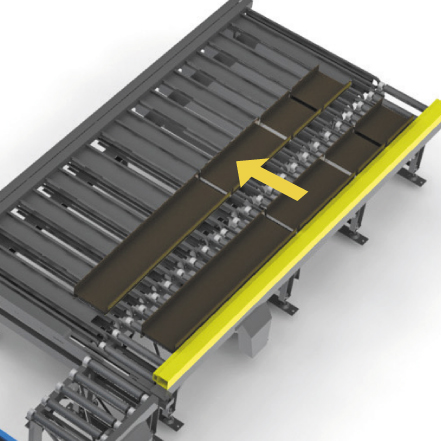

LIFT & CARRY SYSTEM

CHAIN SYSTEM

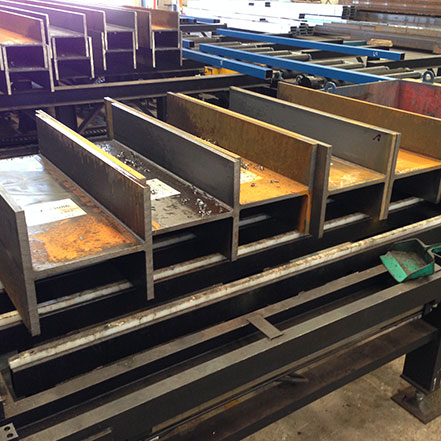

PARTS EJECTOR