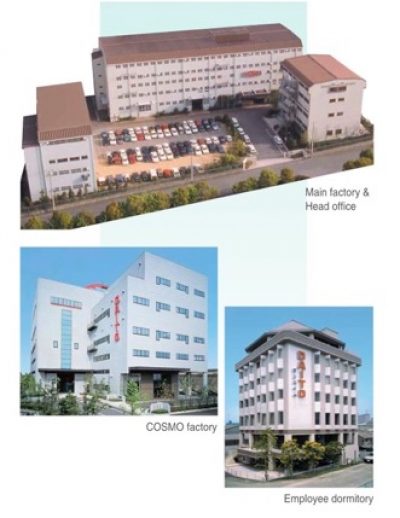

DAITO SEIKI

Made in Japan.

Daito are the worlds premier manufacturer of structural steel drilling, sawing and coping machines. Daito is made in Japan (the worlds largest structural steel market) and to be the best in this market, machine design, quality and longevity has to also be the best.

PRESIDENT