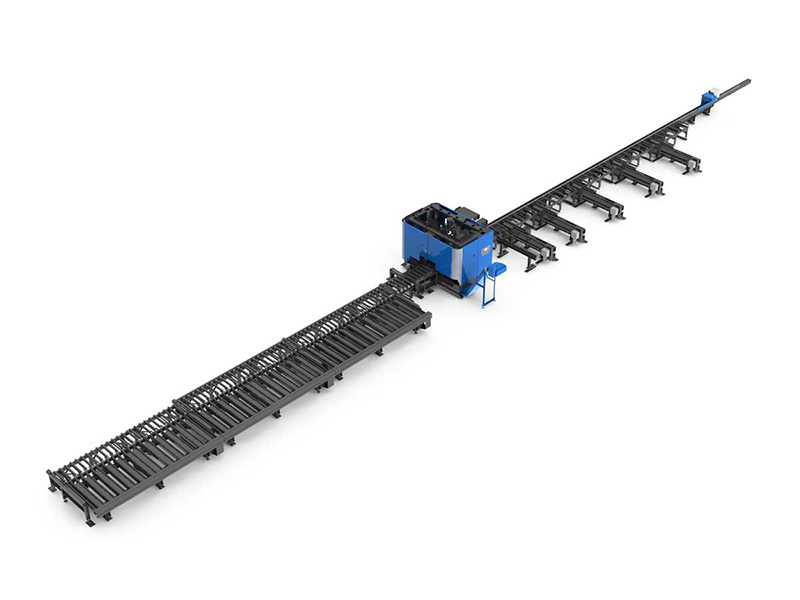

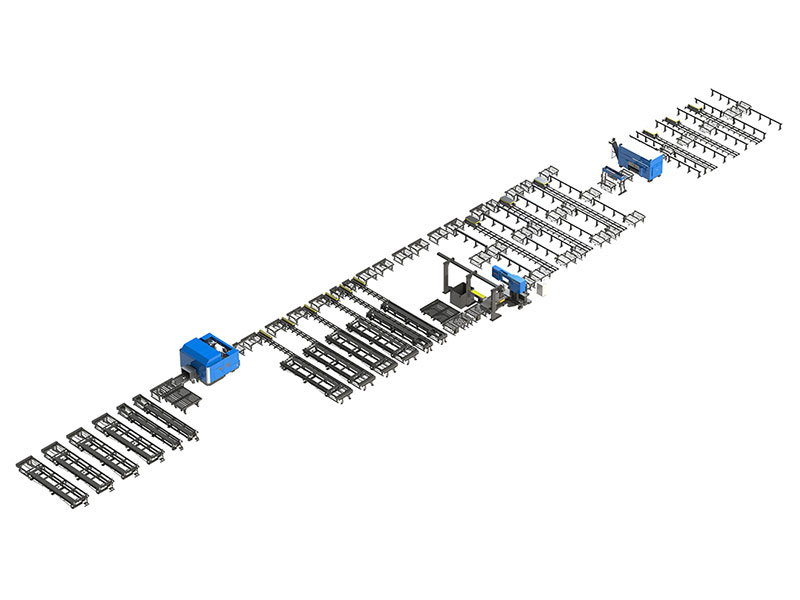

DAITO DASP

FULLY AUTOMATED STRUCTURAL STEEL PROCESSING

AUTOMATED PRODUCTION

A single operator can harness the power of all machines in a production line with DASP. Data is shared between machines to synchronise throughput times.

REDUCED LABOUR

By connecting machines with automated material transport systems and distributing production data instantly to all machines, overall labour requirements are minimized.

INCREASED EFFICIENCY

Daito's DASP accelerates ROI by keeping machines running at peak efficiency, raising your profit margins.

DRILLING - SAWING - COPING - BLASTING

DRILLING - SAWING - COPING

DRILLING - SAWING

DRILLING - SAWING - GRINDING - SHOT BLASTING

DRILLING - SAWING - GRINDING - BEVELING

SAWING - BEVELING